Our business model

Competitive advantages

Viscofan's progress is viewed from the perspective of achieving sustainable competitive advantages, which are the result of the work and commitment of an exceptional team that has offered the best of each individual for over 40 years, making Viscofan the leader in the sector.

Viscofan’s products look simple and are simple to use. This belies the sophisticated technology underlying the manufacturing process which only a few companies worldwide have developed.

The cold meat production sector requires high performance products at very competitive costs, in order to enable large scale production. Meeting this demand implies a huge technological and development challenge that Viscofan performs successfully as the largest casings supplier, and the only one with the technological capacity to offer the four main families of casings: cellulose, collagen, fibrous and plastic casings.

Viscofan's position in the constantly-evolving, highly competitive world market is sustained by cutting-edge efforts in research, development and investigation of its technology and products. Only through the application of this philosophy will the company be able to continue advancing in its leadership of innovation in the global customized casings market, benefiting all of its stakeholders.

Constant innovation required by our globalised world must be taken into account. Our products must be compatible and adapt to the food habits and uses of millions of world consumers, their preferences and evolution over time. Viscofan couples its growth as a business with the development of its innovation capability so that it can access the best technologies available on the market, implement them and improve them, and develop its own technologies to create an enduring competitive edge.

At present, there are strategic product and technology development projects across the entire casings range in progress (cellulose, collagen, fibrous, plastic and vegetable casings), as well as other diversification products aimed at developing applications that provide Viscofan with the product range required to reinforce its presence in the world market.

At present, there are strategic product and technology development projects across the entire casings range in progress (cellulose, collagen, fibrous, plastic and vegetable casings), as well as other diversification products aimed at developing applications that provide Viscofan with the product range required to reinforce its presence in the world market.

On-going and completed Research, Development and Innovation projects focus mainly on:

- The development of new products according to the target markets defined in the expansion plan, and new generation implementations, designed and oriented towards offering products with differential performance and features.

- The development of active casings that are able to confer functionalities to the product they contain, gaining in efficiency and preventing food waste.

- The development of production alternatives and technological solutions through breakthroughs which allow an increase in added value or significantly reduce production costs for meat casings through modernisation, streamlining and simplification, improving Viscofan’s competitiveness.

- Research in the area of raw materials aimed at developing technological processes that enable an adequate range of materials to manufacture casings, while also taking into account sustainability criteria like their biodegradability or recyclability.

- Technological support for improving existing products and processes, and for the Company’s international expansion, all this adhering to Viscofan’s technological and quality standards and current regulations, as well as the optimisation of production costs.

This activity is supported by the R&D team, which during 2019 on average had 135 people in the whole Group (133 in 2018) throughout all the factories. The corporate research and development centre coordinates, directs and supports the specific research and development activities conducted at each production plant, and coordinates the multidisciplinary teams which exchange best practices, technological knowledge and ideas across product sites.

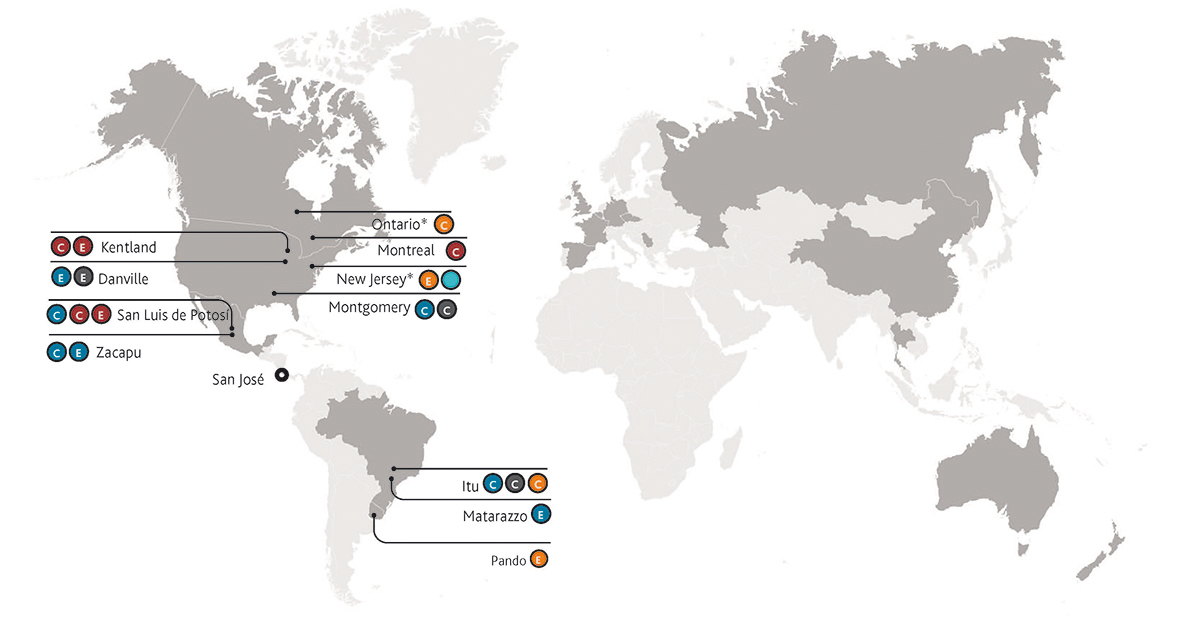

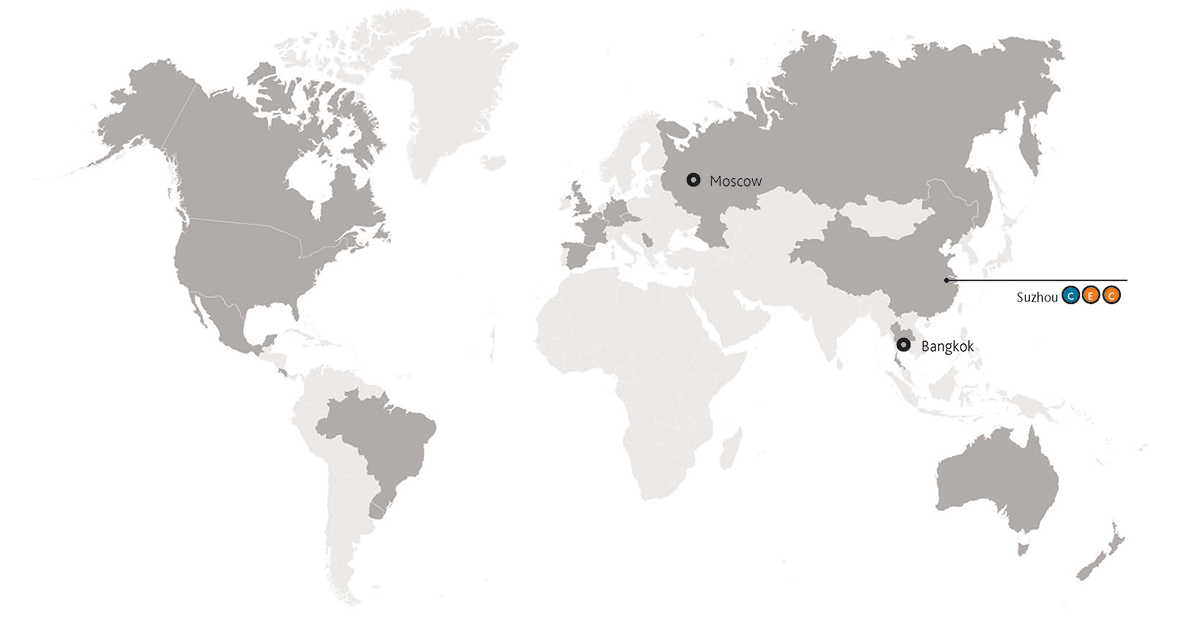

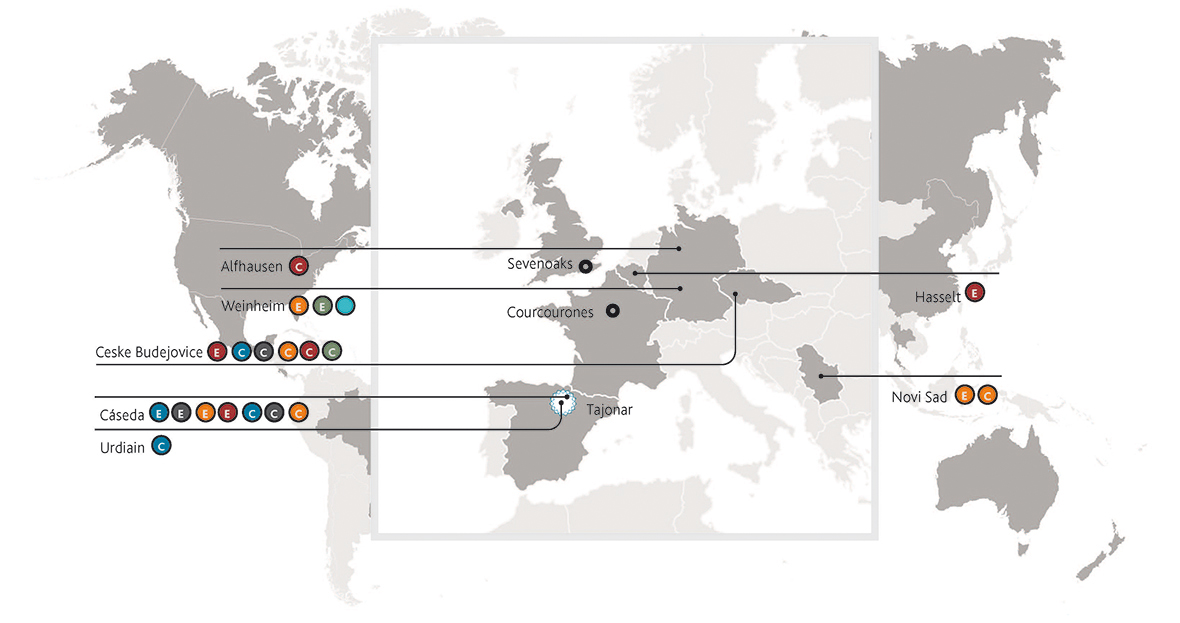

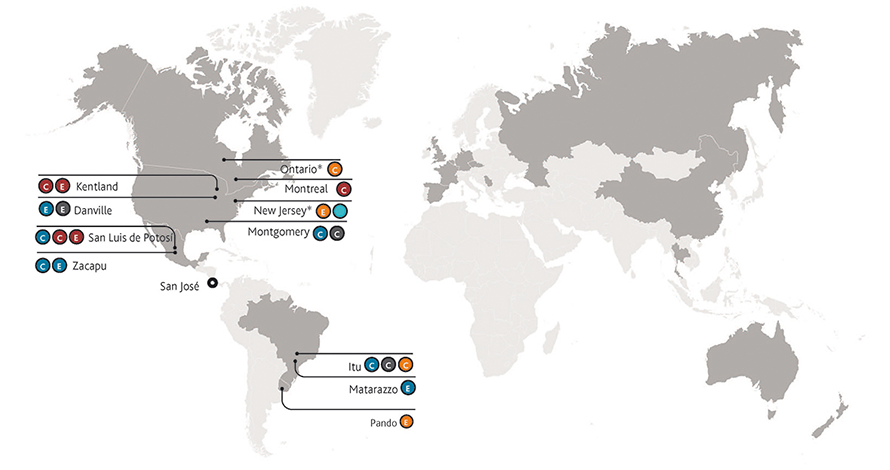

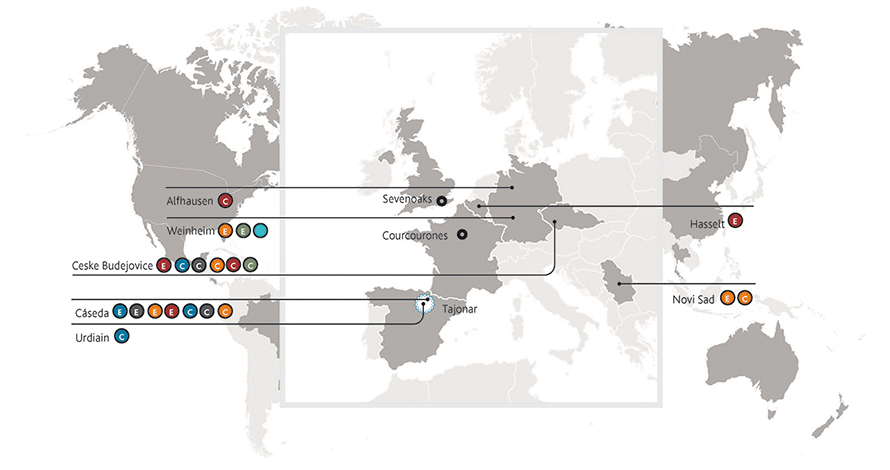

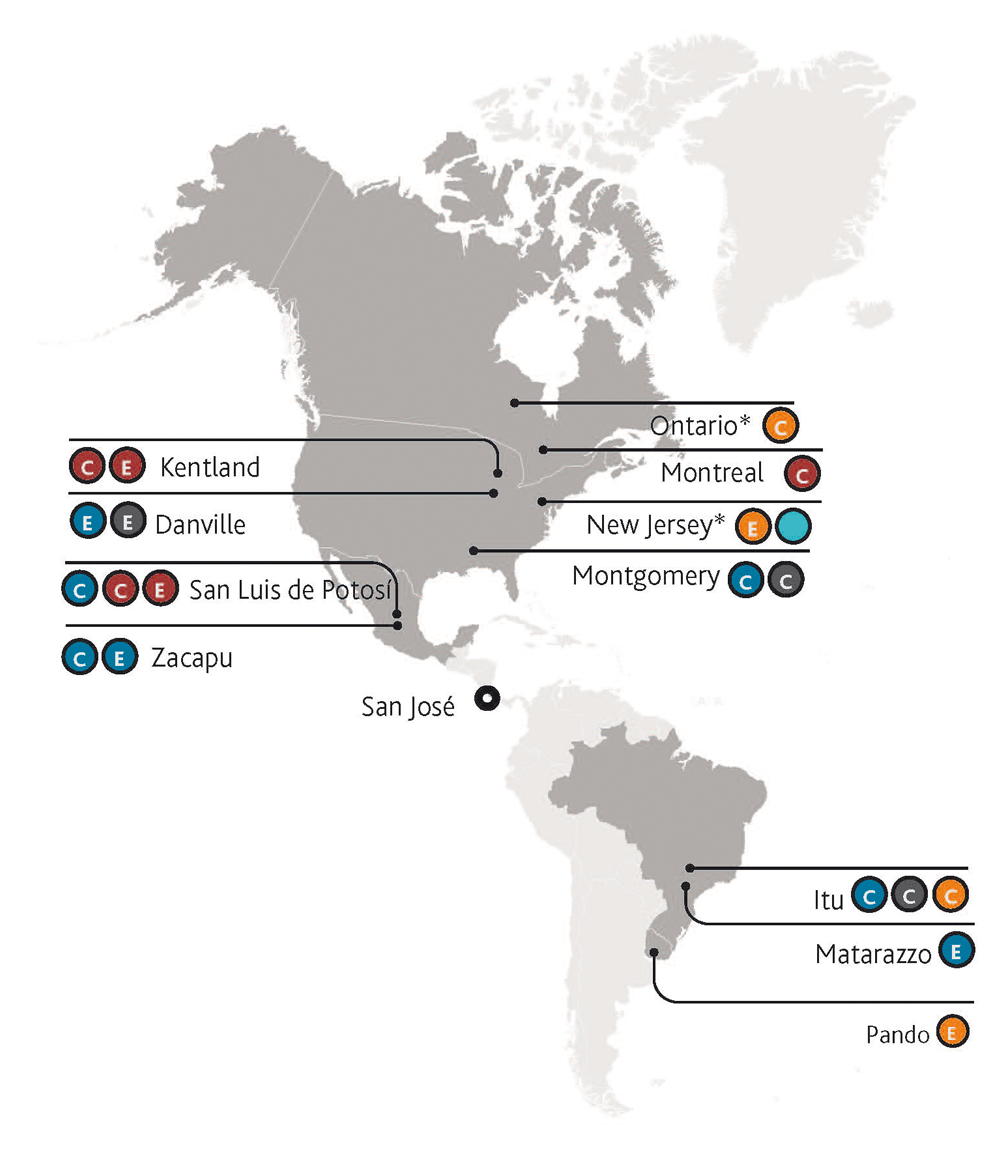

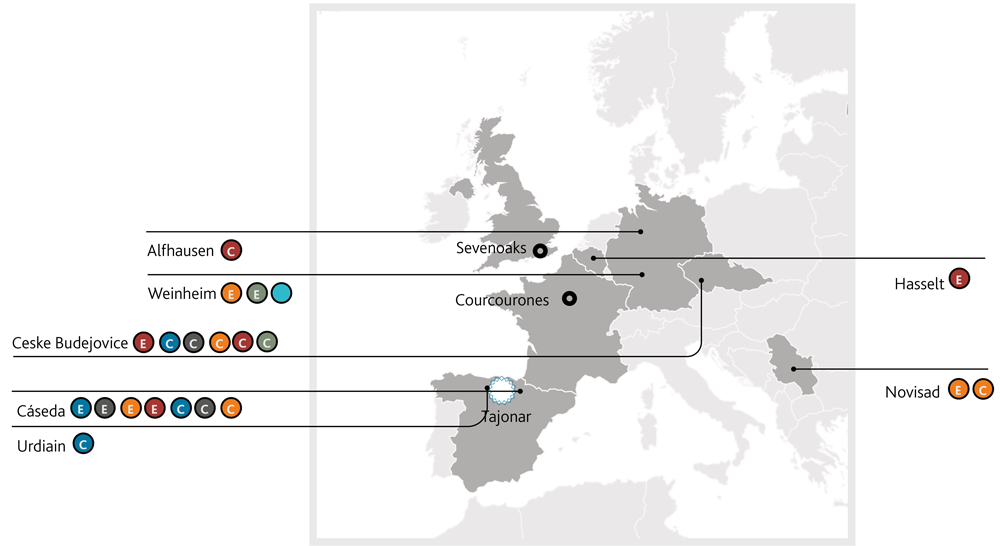

The casings market is global. Our customers are located in more than 100 countries around the world, so providing a quick response adapted to their needs is often a differential element of their purchase decision. To improve this response capacity we have the largest production and sales network in the market.

Interactive map

Mouse over the shaded areas to see more details

In 2019, the Bioengineering Unit made significant progress in the medical and nutraceutical areas, increasing the source of income thanks to the size of the sales network, and also making significant progress in the product research phase.

Innovation in the use of the raw materials we employ also generates growth opportunities beyond the customized casings itself. One example is the new solutions based on the technological knowledge of collagen.

Collagen is the most abundant protein in the human body and therefore there are numerous applications and uses that can be given to this material in people’s benefit. Thus, at Viscofan we are increasingly developing activities around collagen, ranging from medical applications to recent business in advanced nutrition.

In the medical field, the Cardiomesh project - based on the regeneration of heart tissue through the implantation of a medical device made from our collagen membrane - is in the clinical trial phase and reached a major milestone in July 2019. Specifically, the first implantation of this device in Spain was successfully carried out in the Gregorio Marañón Hospital in Madrid in a patient with heart failure due to a myocardial infarction. This is the first of ten interventions planned in this initial phase, the objective of which is to evaluate the safety and tolerance of this new regenerative therapy.

Meet the Cardiomesh project to regenerate heart tissue

We have our own Diversification Division that actively seeks new growth opportunities and collaboration agreements with companies that have outstanding results in this field.

In parallel, in the nutrition market we have made progress with the commercial expansion of COLLinstant®, a high quality collagen hydrolysate that has been quite successful in the market. These collagen hydrolysates are used as a component of nutritional supplements that improve the health of skin, bones and articulations. In the launch year of COLLinstant®, Viscofan has managed to sell its full capacity.

In addition, we have our own Diversification Division that actively seeks new growth opportunities and collaboration agreements with companies that have outstanding results in this field, such as functional casings with antimicrobials or the possibility of extruding collagen with other techniques and forms.