Our business model

MORE TO BE strategy

From this position of leadership, the development of the Viscofan Group is not unconnected with the changes in today's world, which has also affected the needs of our customers, market possibilities and the new world cost and funding structure.

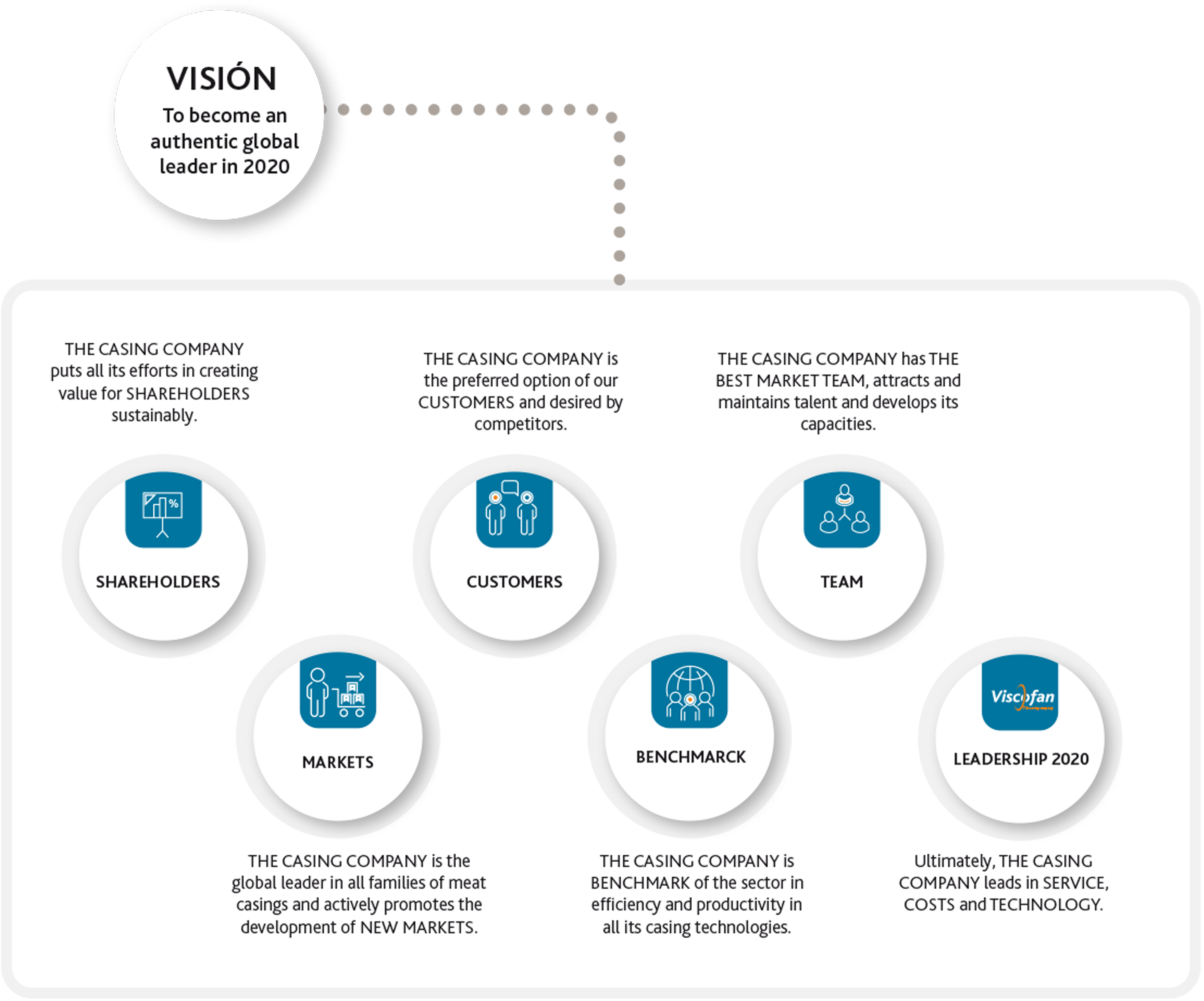

In such a demanding environment, the Viscofan Group bolstered its position of leadership in the sector while developing the activities included in its MORE TO BE 2016-2020 strategic plan, with the objective of leading in all the main casings markets in terms of service, cost, and technology.

The current strategy means a step further in the track record that began with the Be ONE (2009-2011) strategic plan. Under the plan and after these acquisitions, it was decided to restructure operations and draw up management plan to improve economies of scale that the Viscofan Group did not previously have. This approach made Viscofan become a very efficient company, which gave cost optimisation the greater weight of management.

Once that goal was accomplished, Be MORE (2012-2015) strategic plan committed to greater development. The best technological improvements introduced, without giving up competitive cost advantage, gave us a more global presence in collagen and in other families, enabling us to reach other markets and a new scale.

But to be a global leader, we have to lead our key markets. In order to reach our objective, we have to continue to make progress in costs, technology and, of course, step up our level of service .

But to be a global leader, we have to lead our key markets. In order to reach our objective, we have to continue to make progress in costs, technology and, of course, step up our level of service .

But to be a global leader, we have to lead our key markets. In order to reach our objective, we have to continue to make progress in costs, technology and, of course, step up our level of service. And that is exactly what guided the Viscofan Group towards its new vision: Become an authentic global leader: “THE CASING COMPANY”.

Such leadership cannot be achieved without a strong commitment to sustainability. For this reason Viscofan is the first company in the sector to join the United Nations Global Compact for the achievement of Sustainable Development Goals.

Sustainability Action Plan

In 2016, the Company's Board of Directors signed the Corporate Social Responsibility Policy of the Viscofan Group and specific sustainability metrics were incorporated into the bonuses of Viscofan's senior management and key personnel.

Subsequently, an internal work team was set up with external assistance to carry out a sustainability maturity analysis in the Viscofan Group and the materiality analysis.

The growing importance of sustainability within the Viscofan Group is once again reflected in the 2019 financial year with the modification of the Board Regulations and the approval of new regulations for the Audit Committee and the Appointments and Remuneration Committee with specific distribution on the tasks of supervision in matters of sustainability.

Lastly, also in 2019 the Group drew up a Sustainability Action Plan approved by the Board of Directors with the aim of meeting expectations and improving service levels with all our stakeholders: our shareholders, our customers, our employees and, of course, the society in which we operate. Based on continuous dialogue with stakeholders, we have identified the most significant aspects of sustainability and incorporated them within a materiality matrix. In parallel, the dimensions of sustainable value creation (economic, governance, human-social and environmental) have been applied in the performance of our activity, and those Sustainable Development Goals (SDGs) where Viscofan can make a greater contribution have been analysed. The SDGs in place are as follows: SDG 2 Zero Hunger; SDG 6 Clean Water and Sanitation; SDG 8 Decent Work and Economic Growth; SDG 12 Responsible Production and Consumption; SDG 13 Climate Action.

As a result of this process, the Viscofan Group has made specific and measurable commitments in the area of sustainability and in January 2020 created a Sustainability Committee to promote and monitor the Action Plan.

Strategic initiatives

As part of the MORE TO BE Strategic Plan, in 2019 the Viscofan Group carried out various projects with the aim of being a leader in service, cost and technology in its main markets:

Service

This area groups all initiatives aimed at offering solutions to meet needs, and addressable with a greater range of products, greater proximity, better assistance, greater adaptability, etc.

An example of initiatives aimed at improving the service axis is the wide variety of new products launched on the market, including Natur collagen casing for fresh sausages; Marathon Line, extra-long sticks to improve the profitability of our customers; Veggie casing, an edible option for vegans, vegetarians and flexitarians; Vispice, providing spices and aromas to meat products; Plastic transferable casings, among others.

Also with the new plant in Spain started up in 2018, where new cellulose and fibrous technology has been developed and installed. This project allows us to develop new products for the market, as well as gain proximity with European fibrous customers. In this sense, sales in 2018 and 2019 show a high degree of customer satisfaction.

Since December 2019, the acquisition of the collagen casings division from the Japanese group Nitta Gelatin Inc. allows the Viscofan Group to complete its productive presence of this technology in North America, improving service and proximity to the customers in one of the largest casings markets in the world.

Also, in 2019, Viscofan improved its service and product range in Oceania thanks to the acquisition of Globus companies in Australia and New Zealand, a geographic complement to improve proximity in the region. With this acquisition, Viscofan incorporated its main distributor in these countries, which has a long history as a supplier of casings, films and bags, among others, as well as a great knowledge in the sale of equipment for the food industry.

Technology

Our productive process of continuous improvement is based on proprietary technology where know-how of people is essential. As a result of this model of continuous improvement, from 2018 the Group has had new casings production technology based on viscose (cellulose and fibrous) in Caseda, Spain. It is a production plant with the most advanced technology in the market for producing these types of casings, and which is an advance for Viscofan in terms of efficiency and productive speed. This project progressed in 2019 as planned, and new cellulose modules have been put into operation, thus lowering production costs from the second half of the year.

Since 2019 Viscofan has a new technological family, Veggie edible casing and whose raw material is of vegetable origin, a raw material different from the four traditional technologies

Here we can also include the 4.0 industry projects undertaken in the Czech Republic and Spain, and the development of new, large-calibre collagen technology in Serbia.

Cost

In 2019, the company continued to promote projects focused on improving costs by seeking savings through the certification of new suppliers and the development of more efficient production technologies.

Further, in 2019 the Viscofan Group has faced an environment of inflation in the cost of energy and of CO2 emission allowances as well as wage inflation in certain countries. The production improvements achieved in 2019, including the new Cáseda plant, have partially offset this increase in production input costs. In addition, in line with this cost context, commercial activity has sought to increase prices in a wide customer base.